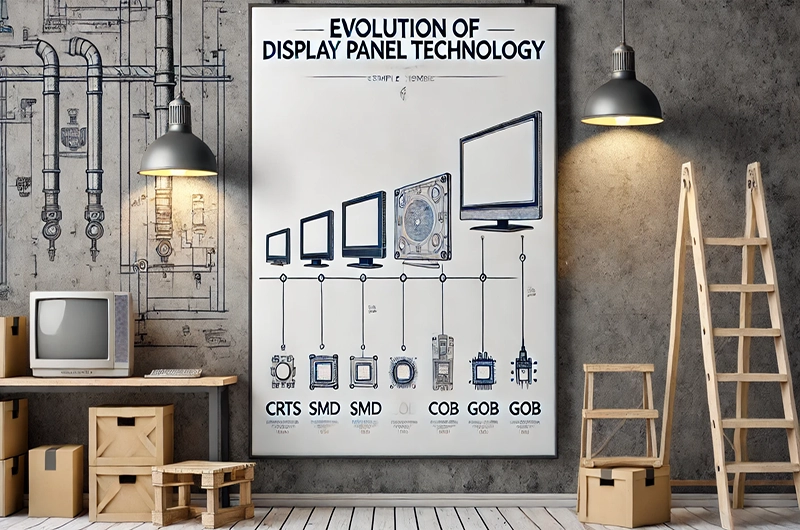

The evolution of display panel technology has been pivotal in shaping modern visual communication, especially in industrial and large-scale applications. From the early cathode ray tubes to today’s advanced LED panels, each technological leap has enhanced display performance, durability, and efficiency. This article delves into the history and characteristics of various display technologies, including COB, SMD, and GOB panels, providing a comprehensive overview for professionals in the field.

The Dawn of Display Technology: Cathode Ray Tubes (CRTs)

In 1897, physicist Karl Ferdinand Braun introduced the cathode ray tube (CRT), marking the inception of electronic display technology. CRTs became the cornerstone of visual displays throughout the 20th century, utilized extensively in televisions and computer monitors. These devices operated by directing electron beams onto a phosphorescent screen, creating images through controlled electron emissions.

Despite their widespread adoption, CRTs had notable limitations. They were bulky, and heavy, and consumed significant power, making them less suitable for large-scale industrial applications where space and efficiency were paramount. The quest for more compact, energy-efficient, and high-performance display solutions led to the development of alternative technologies.

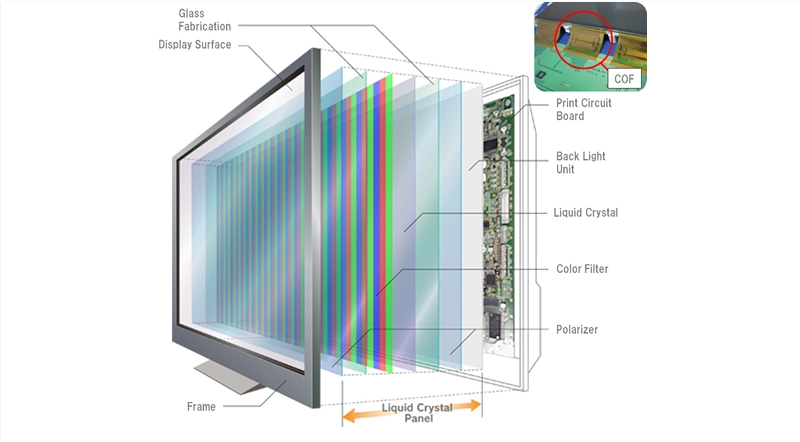

The Rise of Liquid Crystal Displays (LCDs)

The 1960s witnessed the advent of Liquid Crystal Display (LCD) technology. LCDs utilize liquid crystals modulated by electric currents to control light passage, enabling thinner and more energy-efficient displays compared to CRTs. This innovation revolutionized various industries, offering a viable solution for applications requiring compact and efficient display systems.

Over time, advancements such as Twisted Nematic (TN) and In-Plane Switching (IPS) technologies enhanced LCD performance, improving color accuracy and viewing angles. However, for large-scale industrial displays, LCDs often fell short in terms of brightness and durability, prompting the exploration of more robust technologies.

Light-Emitting Diodes (LEDs): A New Era

The discovery of electroluminescence in 1907 paved the way for Light-Emitting Diodes (LEDs), but it wasn’t until the 1960s that LEDs became practical for display purposes. LEDs offer significant advantages, including higher brightness, longer lifespan, and greater energy efficiency, making them ideal for large-scale and industrial applications.

The development of LED technology led to various packaging methods, each with unique characteristics tailored to specific application needs.

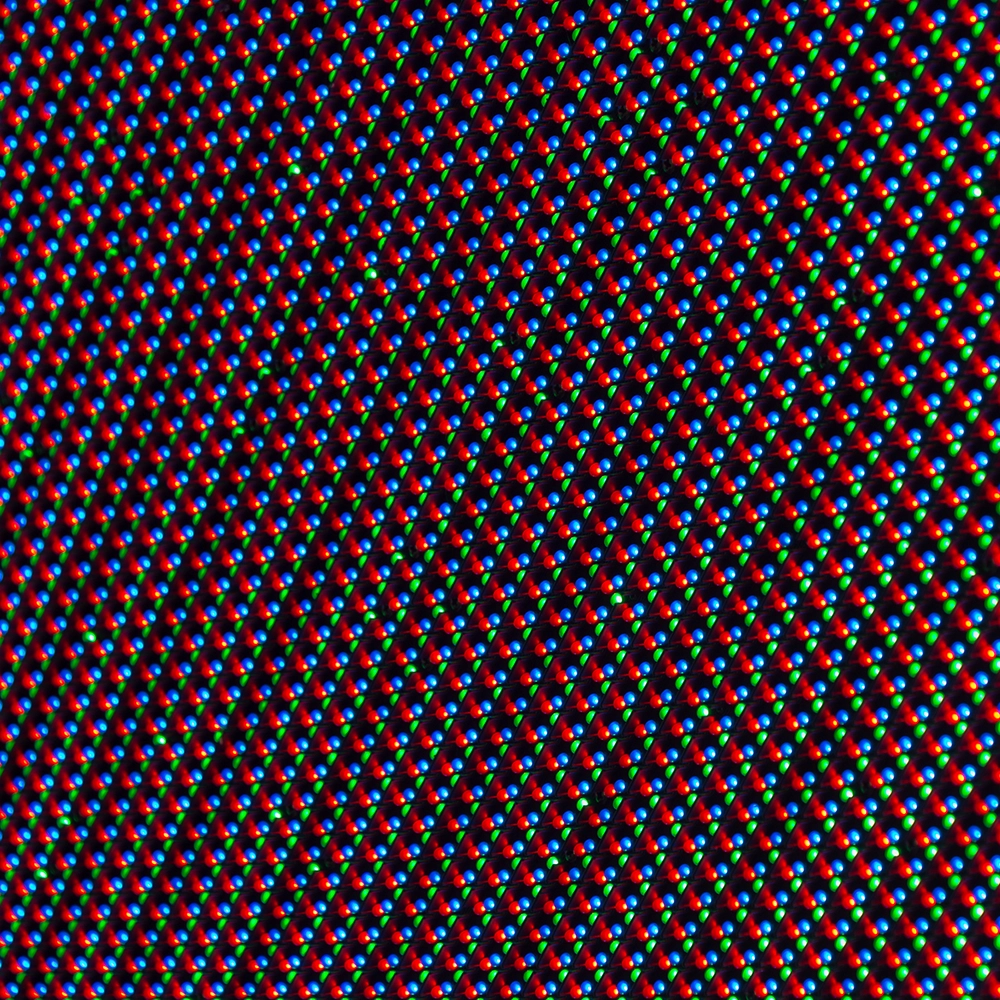

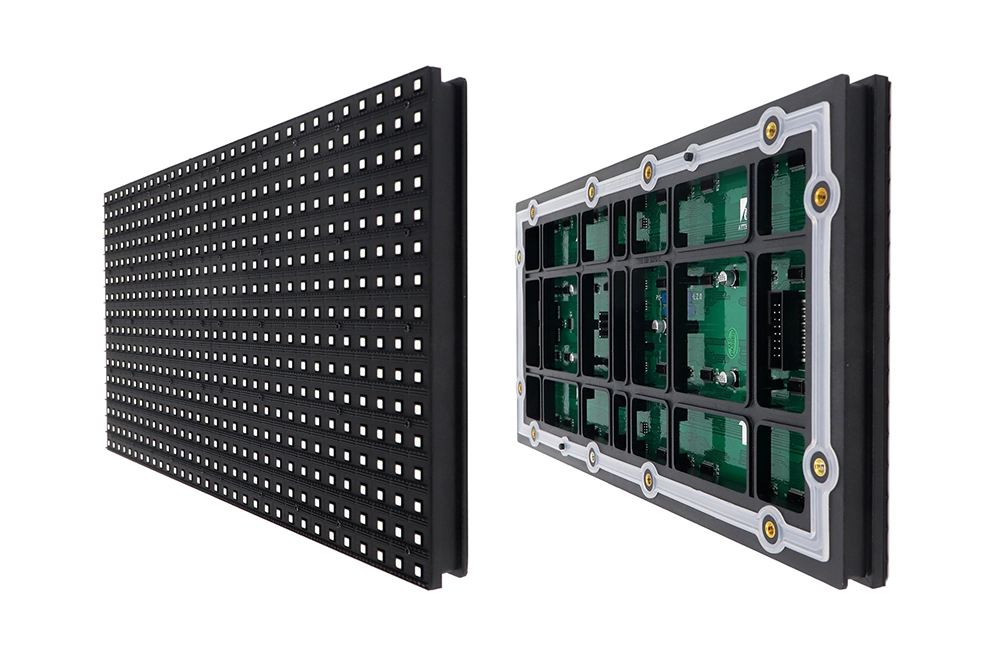

Surface-Mounted Device (SMD) Panels

Surface-mounted device (SMD) technology involves mounting LED chips directly onto the surface of a printed circuit board (PCB). Each SMD component typically contains red, green, and blue diodes, allowing for the creation of a full-color spectrum. This configuration enables high-resolution displays with excellent color uniformity, making SMD panels popular in both indoor and outdoor large-scale applications.

SMD panels are renowned for their versatility and reliability. They offer wide viewing angles and are capable of producing high brightness levels, essential for environments with varying lighting conditions. Additionally, their modular design facilitates easy maintenance and scalability, accommodating diverse industrial requirements.

Chip-On-Board (COB) Panels

Chip-on-board (COB) technology represents a significant advancement in LED display engineering. In COB panels, multiple LED chips are directly bonded onto a substrate, forming a single module. This design enhances thermal management, allowing for a higher density of LEDs and resulting in superior brightness and improved color consistency.

COB panels are particularly advantageous in industrial settings where durability and performance are critical. The integrated design reduces the likelihood of component failure, and the enhanced heat dissipation extends the lifespan of the display. Furthermore, COB technology contributes to a seamless display surface, minimizing gaps between LEDs and providing a more uniform visual output.

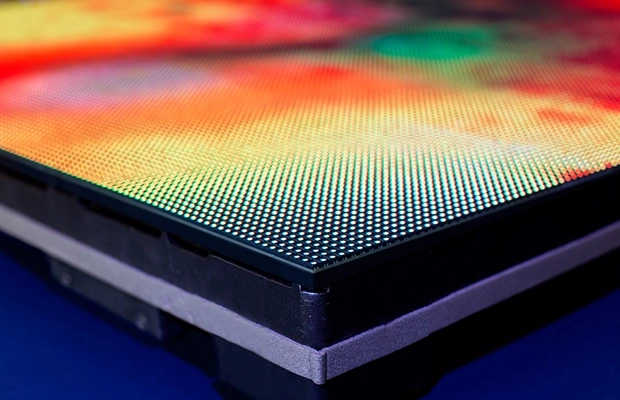

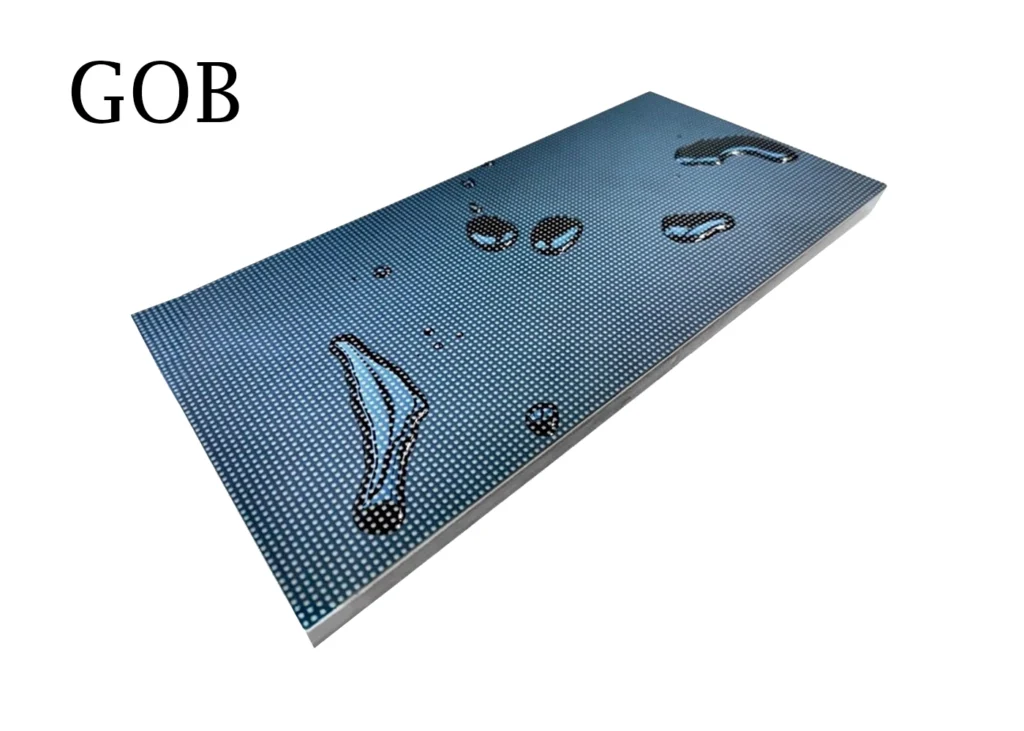

Glue-On-Board (GOB) Panels

Glue-on-board (GOB) technology involves applying an epoxy resin layer over the surface of SMD modules. This protective coating shields the LEDs from environmental factors such as moisture, dust, and physical impact, significantly enhancing the durability of the display. GOB panels are engineered to withstand challenging conditions, making them suitable for demanding industrial environments.

The protective layer in GOB panels also contributes to improved visual performance by reducing glare and enhancing contrast. This ensures clear and vibrant displays, even in high ambient light conditions. Additionally, the robust construction of GOB panels minimizes maintenance requirements, offering a cost-effective solution for large-scale installations.

Advancements in Display Panel Technologies

The continuous evolution of display panel technologies has led to innovations that address specific industrial needs. For instance, the development of Mini-LED and Micro-LED technologies offers higher brightness and energy efficiency, catering to applications requiring superior visual performance. These advancements provide more options for industries seeking tailored display solutions.

Moreover, the integration of smart technologies into display panels has enabled features such as real-time data monitoring and interactive interfaces. These capabilities enhance operational efficiency and user engagement, further solidifying the role of advanced display panels in modern industrial applications.

Considerations for Selecting Display Panels in Industrial Applications (Continued)

When selecting display panels for industrial use, several factors must be considered to ensure optimal performance and longevity. These include environmental conditions, viewing distance, resolution requirements, and maintenance capabilities. Understanding the specific demands of the application is crucial in choosing the appropriate technology, whether it be SMD, COB, or GOB panels.

Additionally, energy efficiency and total cost of ownership are critical considerations. While the initial investment in advanced technologies like COB or GOB panels may be higher, their durability and lower maintenance needs can result in cost savings over time. Therefore, a comprehensive assessment of both short-term and long-term needs should guide the decision-making process.

Applications of Display Panels in Industrial Settings

Industrial environments require reliable and high-performing display panels to handle diverse applications such as data visualization, control systems, and public information displays. SMD panels are often favored for indoor command centers due to their high resolution and color accuracy, ensuring clear visual output for real-time data monitoring.

On the other hand, COB and GOB panels excel in outdoor or harsh environments. Their enhanced durability and resistance to weather conditions make them suitable for applications such as large-scale digital signage, factory monitoring systems, and event displays. These panels not only provide robust performance but also help reduce downtime due to maintenance or environmental damage.

Future Trends in Display Panel Technology

As the demand for more efficient and versatile display solutions grows, ongoing advancements in panel technology are expected to play a significant role in shaping industrial applications. The emergence of Micro-LED technology, for instance, offers the potential for higher brightness, superior energy efficiency, and even thinner display profiles. This makes it a promising candidate for next-generation industrial displays.

Similarly, integration with IoT (Internet of Things) technologies is paving the way for smart display systems. These systems allow real-time monitoring, remote management, and enhanced interactivity, further expanding the functionality and usability of industrial display panels. Future innovations will likely focus on achieving higher performance while reducing costs, and ensuring accessibility for a wider range of industries.

Conclusion

Display panels have come a long way since the advent of CRT technology. Innovations such as SMD, COB, and GOB panels have revolutionized the industry, each offering unique characteristics suited for specific applications. From high-resolution indoor displays to rugged outdoor solutions, these technologies continue to meet the diverse demands of industrial and large-scale settings.

About Kaddaki

Kaddaki is a leader in display technology, offering state-of-the-art solutions tailored to industrial and commercial applications. With a focus on innovation, reliability, and customer satisfaction, Kaddaki provides cutting-edge display panels, including SMD, COB, and GOB technologies. Whether you’re looking for high-resolution indoor displays or durable outdoor systems, Kaddaki’s expertise ensures the ideal solution for your needs. Visit Kaddaki to explore their range of advanced display products and services

No comment